Most people don’t shop for curtain rods because they’re excited. They shop for them because something went wrong.

The rod bent. The brackets came loose. The curtain doesn’t slide smoothly. Or worse, the whole thing came down one morning.

For manufacturers, curtain rods sit in an interesting position. They’re not decorative items customers show off, but when they fail, they’re impossible to ignore. That’s exactly why this category deserves more serious attention than it usually gets.

So What Is a Curtain Rod, Really?

On the surface, a curtain rod is simple. It’s a bar mounted above a window to hold curtains.

But in real use, it’s a load-bearing, moving, wall-mounted product that deals with weight, friction, vibration, and daily handling.

A basic curtain rod system usually includes the rod itself, mounting brackets, finials, screws, and sometimes extension joints. Each part plays a role, and when one is poorly designed, the whole setup feels cheap or unreliable.

This is why curtain rods are less about looks and more about structure than most buyers realize.

Why Does This Matter More Than People Think?

Because curtain rods live in the “install once, use every day” category.

Customers don’t want to think about them again after installation. If they do, it’s usually because something isn’t working.

From a manufacturer’s point of view, problems often show up as:

- - Sagging rods after a few months

- - Brackets pulling out of the wall

- - Noise or resistance when opening curtains

- - Coating damage or corrosion over time

Each of these issues creates returns, complaints, or bad reviews—often long after the sale.

That’s why curtain rods aren’t a “low-risk” product just because they look simple.

When Do People Actually Use Curtain Rods the Most?

Most manufacturers underestimate usage frequency.

Curtain rods aren’t touched once a day. In many homes, they’re used multiple times—morning, evening, and sometimes throughout the day.

They’re also under constant load. Heavy blackout curtains, thermal curtains, or layered fabric setups add weight that stays there 24/7.

In rental properties, hotels, and offices, usage is even rougher. Curtains get pulled harder, adjusted more often, and replaced less carefully.

This is why “normal household use” is not a reliable design assumption.

How Does a Curtain Rod System Actually Work?

Weight Distribution Comes First

The rod doesn’t just hold curtains—it transfers weight to the brackets, and from there into the wall.

If the rod wall thickness is too thin or the bracket spacing is poorly calculated, sagging is almost guaranteed.

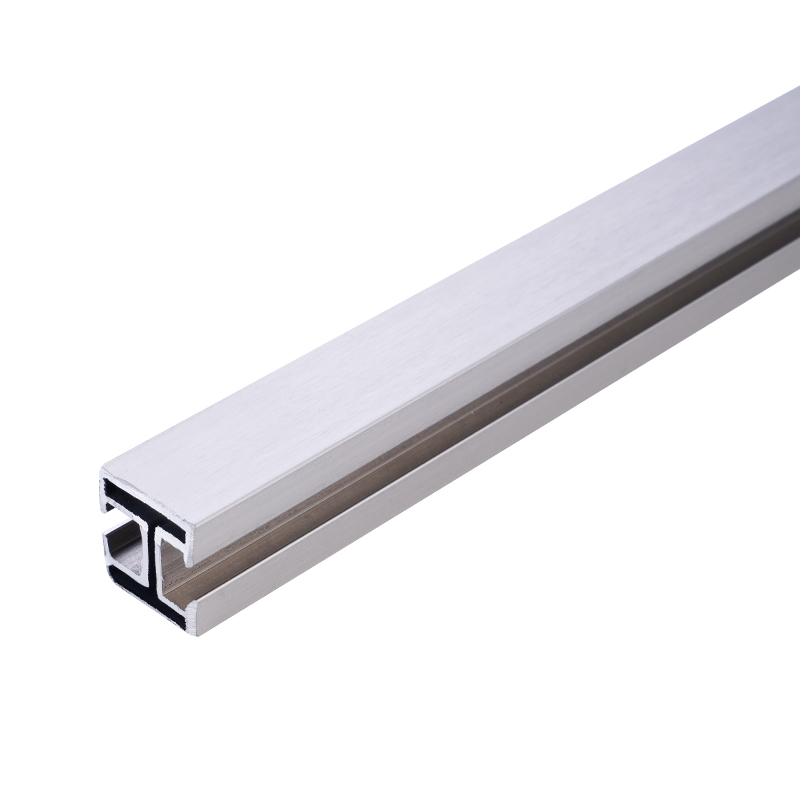

Extension Mechanisms Matter

Many curtain rods are telescopic. This makes shipping easier and fits more window sizes.

But extension joints are also weak points. Poorly designed joints cause bending, uneven load, or visible seams once installed.

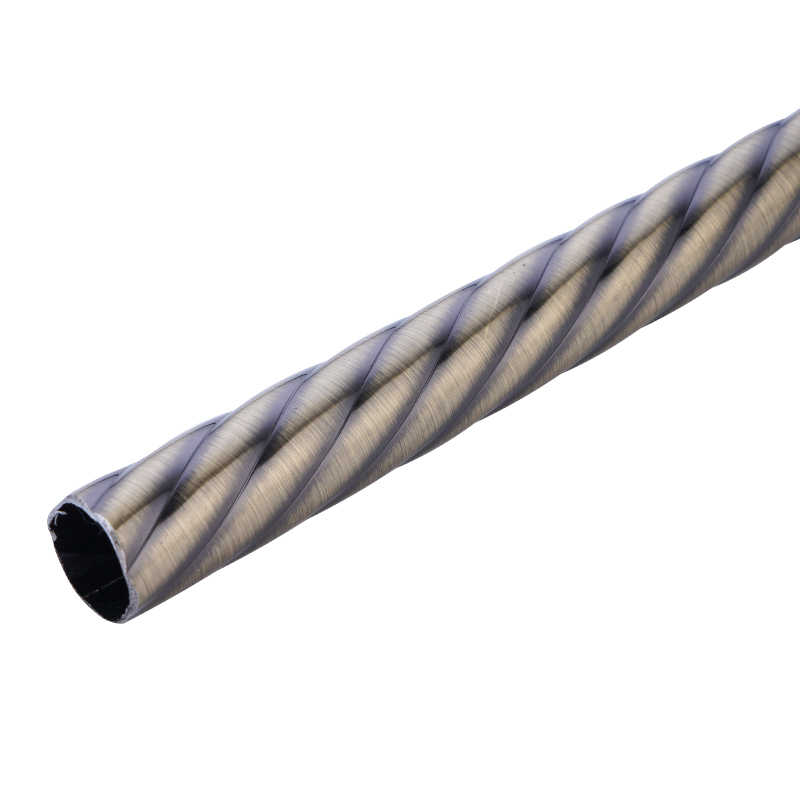

Surface Finish Isn’t Just Decorative

Paint, plating, or coating protects the rod from moisture, dust, and friction.

In humid environments, low-quality finishes lead to rust, peeling, or discoloration that customers notice quickly.

What Are the Real Trade-Offs in Curtain Rod Manufacturing?

This is where manufacturers make strategic decisions, whether they realize it or not.

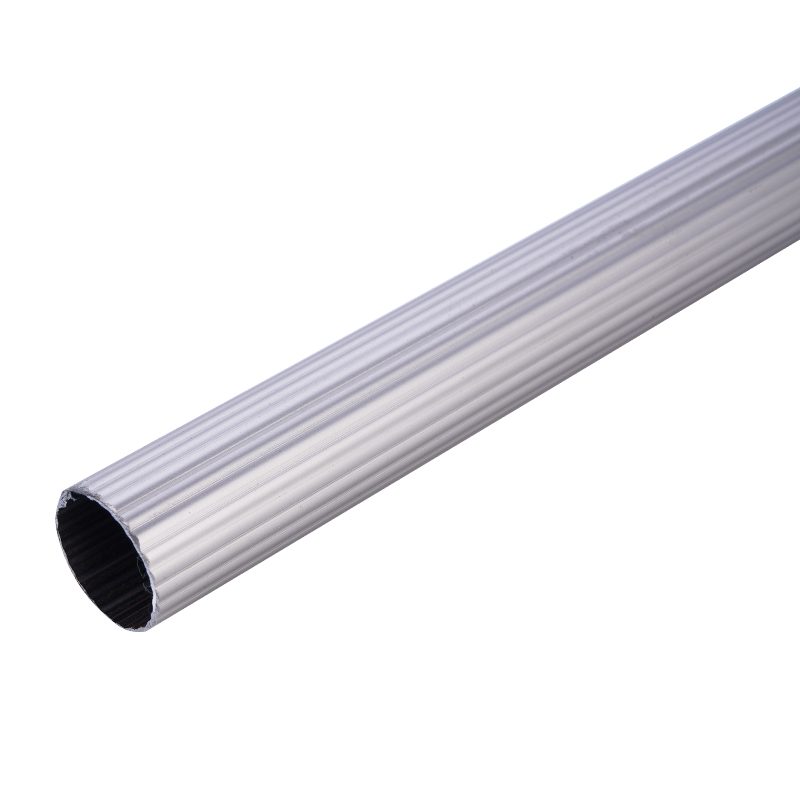

Thin vs. Thick Wall Tubes

Thinner tubes reduce material cost and weight, but they bend more easily.

Thicker tubes cost more but feel solid, especially with heavy curtains.

Steel vs. Aluminum

Steel rods offer strength and stability, while aluminum is lighter and corrosion-resistant.

The choice depends on target market, curtain weight, and installation environment.

Universal Fit vs. Purpose Design

One-size-fits-all designs simplify inventory.

But purpose-designed rods for bay windows, extra-wide spans, or ceiling mounting often perform better and reduce complaints.

Where Do Most Curtain Rod Problems Come From?

Interestingly, many failures don’t come from the rod itself.

They come from mismatched systems.

Examples include:

- - Heavy curtains paired with lightweight rods

- - Long spans without center support

- - Decorative brackets that lack structural strength

- - Inadequate wall anchors for drywall installations

From the customer’s perspective, all of these feel like “bad product,” even if only one component is the issue.

What Should Manufacturers Pay Attention To?

Real Load Testing, Not Assumptions

Testing with actual curtain weights, not theoretical limits, reveals problems early.

Clear Weight Ratings

Many customers don’t know how heavy their curtains are.

Clear guidance reduces misuse and dissatisfaction.

Bracket Design Is Not an Afterthought

Strong rods with weak brackets still fail.

Bracket thickness, screw placement, and wall contact area matter more than decoration.

Installation Experience Shapes Product Perception

If installation is frustrating, customers blame the product.

Well-designed hardware and clear instructions reduce returns more than better packaging.

How Is the Market Changing?

Curtain rods are quietly shifting from basic hardware to semi-structural home components.

Customers are asking for:

- - Higher load capacity for layered curtains

- - Minimalist designs that don’t sacrifice strength

- - Adjustable systems that don’t feel flimsy

- - Finishes that last in humid or coastal environments

Manufacturers who treat curtain rods as engineered products—not accessories—are better positioned to meet these expectations.

Final Thoughts

Curtain rods don’t get much attention when they work.

That’s exactly the point.

For manufacturers, success in this category isn’t about trends or decoration. It’s about reliability, structure, and understanding how the product behaves after months or years of daily use.

When a curtain rod disappears into the background of everyday life, that’s usually a sign it was designed and made properly.