Introduction to Curtain Rings and Their Applications

Curtain rings are essential components for hanging and smoothly operating curtains in both residential and commercial settings. They provide the mechanism by which curtains glide along rods or tracks, ensuring ease of use and aesthetic appeal. While typically used indoors, questions often arise regarding their suitability for outdoor spaces or environments with high moisture, such as bathrooms or kitchens. The choice of material, finish, and design significantly impacts their performance under such conditions.

Materials Used in Curtain Rings

Curtain rings are manufactured from a variety of materials, including metals like stainless steel, aluminum, and brass, as well as plastics, wood, and composite materials. Each material offers different levels of resistance to environmental factors such as humidity, rain, and temperature fluctuations. Metals like stainless steel and aluminum have inherent corrosion resistance, making them more appropriate for damp or outdoor settings. Plastic rings are generally resistant to water but may degrade under prolonged exposure to UV light. Wooden rings, while visually appealing, require treatment or coating to withstand moisture without warping or cracking.

Corrosion Resistance and Durability

Corrosion resistance is a key consideration for curtain rings in outdoor or damp environments. Stainless steel rings contain chromium, which forms a passive oxide layer protecting the metal from oxidation. Aluminum naturally forms a protective oxide layer, though anodized or coated finishes can enhance resistance to moisture and environmental wear. Brass may tarnish over time but can be treated with clear coatings to maintain its appearance. Plastic rings, especially those made of high-quality polymers, resist rust and corrosion entirely but may become brittle or discolored with prolonged UV exposure.

Common Curtain Ring Materials and Outdoor Suitability

| Material | Moisture Resistance | UV Resistance | Notes |

|---|---|---|---|

| Stainless Steel | High | Moderate | Suitable for humid indoor and sheltered outdoor use |

| Aluminum | High | Moderate | Anodized finish improves long-term outdoor performance |

| Plastic (Polypropylene, PVC) | High | Variable | Resistant to moisture but may discolor or weaken under prolonged sun exposure |

| Wood | Low to Moderate | Low | Requires protective coating or sealant for damp environments |

| Brass | Moderate | Moderate | May tarnish but can be treated with protective coatings |

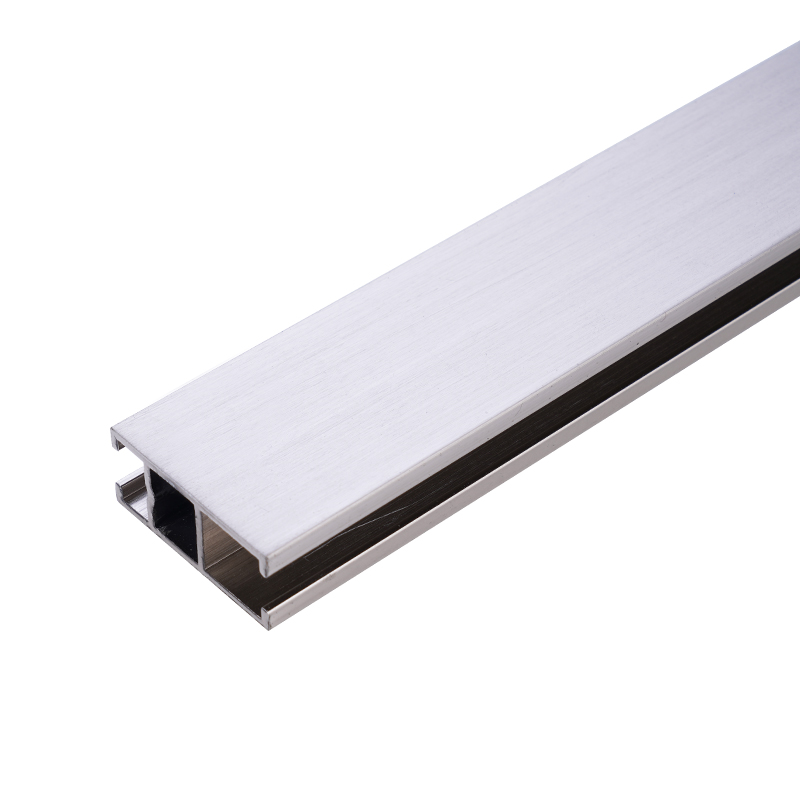

Coatings and Finishes for Enhanced Performance

Beyond the base material, the surface finish of curtain rings affects their resistance to moisture and outdoor conditions. Powder coating, electroplating, and anodizing create a barrier against corrosion and wear. For example, powder-coated aluminum rings are more resistant to rain and humidity compared to untreated aluminum. Similarly, stainless steel rings with brushed or passivated finishes maintain appearance and resist surface rust. Plastic rings can incorporate UV stabilizers to reduce brittleness and fading when exposed to sunlight.

Design Considerations for Outdoor or Damp Use

The design of the curtain ring also influences its performance in moist conditions. Rings with enclosed or smooth surfaces reduce water accumulation, preventing corrosion and facilitating cleaning. Ventilation holes or hollow designs in some rings help reduce trapped moisture. The method of attachment to the curtain rod or track, such as hooks, clips, or integrated sliding mechanisms, should also be corrosion-resistant and easy to maintain. Ensuring smooth movement is important for both function and longevity.

Environmental and Maintenance Factors

Curtain rings in outdoor or humid indoor areas may be exposed to rain, condensation, or frequent temperature changes. Regular cleaning and inspection can prevent buildup of dirt, mineral deposits, or mildew. Rinsing metal or plastic rings with water and drying them prevents surface degradation. Avoiding prolonged contact with harsh chemicals, such as pool chlorine or cleaning agents, further prolongs the life of the rings. Maintenance frequency should be adjusted depending on the intensity of environmental exposure.

Applications in Outdoor and Damp Areas

Curtain rings designed for moisture resistance are commonly used in bathrooms, kitchens, balconies, patios, or sunrooms. Stainless steel and anodized aluminum rings are preferred for outdoor covered areas, while plastic rings with UV stabilizers are suitable for open-air environments. In bathrooms, proper ventilation reduces condensation, further protecting the rings. For outdoor decks or gazebos, ensuring rings are covered or sheltered extends their functional lifespan and maintains aesthetic quality.

Recommended Curtain Rings for Specific Environments

| Environment | Recommended Material | Maintenance Tips |

|---|---|---|

| Bathroom | Stainless Steel, Plastic | Rinse with water, dry regularly to prevent condensation buildup |

| Patio or Balcony | Anodized Aluminum, UV-stabilized Plastic | Clean dirt and debris; protect from direct sun if possible |

| Kitchen | Stainless Steel, Powder-coated Metal | Wipe with mild detergent; avoid harsh chemicals |

| Open Outdoor Spaces | Plastic with UV Stabilizer | Inspect for fading or brittleness; replace if deteriorated |