Introduction to curtain brackets

Curtain brackets are essential hardware components used to support curtain rods, allowing curtains or drapes to be installed securely. They provide the structural support required to hold the weight of window coverings while enabling smooth operation. The suitability of curtain brackets for walls or ceilings of varying thicknesses is an important consideration, as different installation surfaces present unique challenges in terms of load-bearing capacity, anchoring methods, and stability.

Material composition and durability

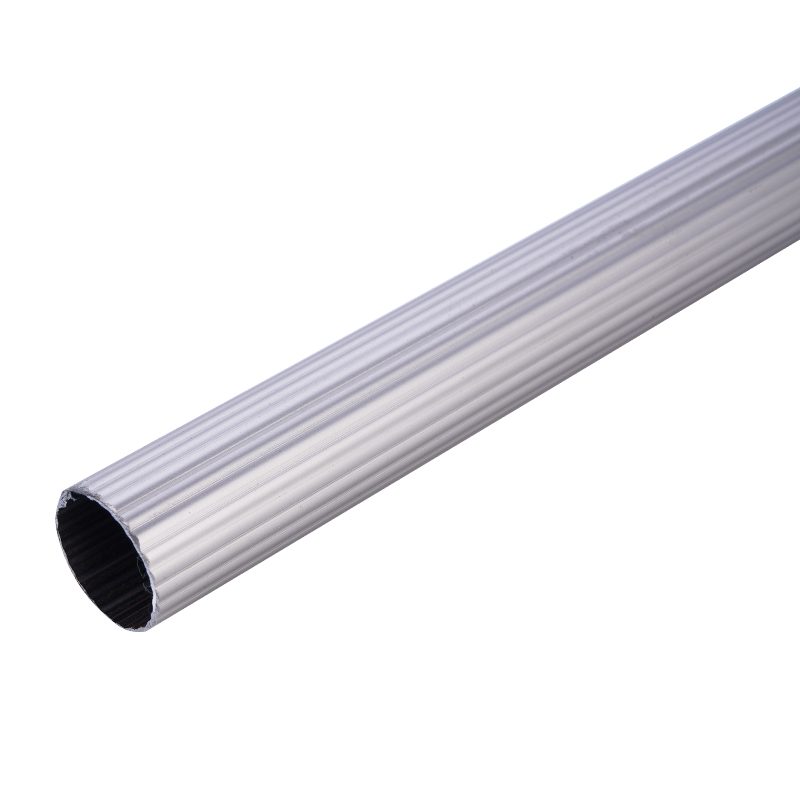

Curtain brackets are commonly made from metals such as steel, aluminum, or zinc alloys, as well as high-strength plastics for lighter applications. The choice of material affects the bracket's strength, flexibility, and resistance to deformation. Durable materials are essential for supporting heavy curtains or layered drapery, particularly on walls or ceilings with uneven thickness. Corrosion-resistant coatings or finishes also help maintain the bracket’s structural integrity over time, especially in areas exposed to humidity or temperature fluctuations.

Design adaptability for varying surfaces

Modern curtain brackets are designed with adaptability in mind. Adjustable arms, extendable rods, and versatile mounting plates allow brackets to accommodate walls or ceilings of different thicknesses. Brackets may include slotted holes or multi-point mounting options to adjust the positioning relative to the installation surface. This flexibility ensures that curtains hang evenly, even when the mounting surface is not uniform, and allows installation in older buildings or renovations with variable wall or ceiling dimensions.

Load-bearing considerations

The load-bearing capacity of a curtain bracket depends on both its design and the strength of the installation surface. Brackets installed on thicker walls or reinforced ceilings can support heavier curtains without risk of detachment. Conversely, thinner walls or lightweight ceiling materials may require additional support, such as wall anchors or expansion plugs. Understanding the interaction between the bracket, the fasteners, and the surface is essential for maintaining safe and secure installations across various thicknesses.

Anchoring methods for different surface types

Proper anchoring is crucial for curtain brackets installed on walls or ceilings of varying thicknesses. For solid concrete or brick walls, expansion bolts or screws with anchors provide strong fixation. Drywall or plasterboard surfaces require specialized anchors, such as toggle bolts or molly screws, to distribute load and prevent pull-out. Ceilings, which may include plaster, wood, or suspended panels, also necessitate careful selection of fasteners to ensure the bracket remains stable. Bracket designs often incorporate multiple anchor points to enhance safety and stability regardless of the surface thickness.

Impact of surface thickness on bracket selection

Surface thickness influences the type and size of bracket that can be installed. Thicker walls provide more material for screws or bolts to grip, allowing for heavier-duty brackets. Thinner surfaces may necessitate brackets with wider base plates or additional reinforcement to spread load across a larger area. Adjustable brackets are particularly useful in these situations, as they can be repositioned or extended to compensate for the limited material depth, ensuring secure mounting without compromising aesthetics.

Ceiling-mounted curtain brackets

Ceiling-mounted curtain brackets are often used when wall space is limited or when floor-to-ceiling curtains are desired. Installation on ceilings requires consideration of the ceiling material, joist spacing, and the weight of the curtains. Brackets designed for ceiling mounting typically include longer screws or toggle bolts to reach structural support within the ceiling. Adjustable height options allow the bracket to be aligned with varying ceiling thicknesses, ensuring that curtains hang evenly and operate smoothly.

Wall-mounted curtain brackets

Wall-mounted curtain brackets are more common and must accommodate walls of varying thicknesses, including drywall, plaster, or masonry. Brackets with multiple mounting holes provide flexibility to align with wall studs or reinforcement points. For thinner walls, reinforced backplates or anchors are used to distribute load and prevent the bracket from pulling out. The bracket’s design ensures that even lightweight walls can support the curtain’s weight without compromising stability.

Compatibility with different curtain types

The suitability of curtain brackets for varying wall or ceiling thicknesses also depends on the type of curtain being used. Heavier fabrics, such as velvet or layered drapery, require robust brackets and secure anchoring, while lighter fabrics may be supported with simpler designs. Brackets with adjustable extension arms allow the curtain to clear obstructions, such as window frames or molding, while maintaining proper alignment. The versatility of these brackets ensures compatibility with a range of curtain weights and styles across surfaces of different thicknesses.

Ease of installation and adjustment

Modern curtain brackets are designed to simplify installation on surfaces of varying thicknesses. Features such as adjustable screws, slotted holes, and telescoping arms allow installers to fine-tune positioning for optimal curtain alignment. Clear instructions and compatibility with common fasteners ensure that the brackets can be securely mounted without extensive modification to the wall or ceiling. This adaptability reduces installation errors and increases the functional lifespan of the brackets.

Durability under repeated use

Curtain brackets must remain durable under repeated curtain operation, including opening and closing motions, which apply lateral and vertical forces. High-quality materials, reinforced designs, and properly selected fasteners minimize wear and deformation over time. Whether mounted on thick or thin walls or ceilings, durable brackets provide stable support, preventing sagging or loosening that could compromise curtain performance or safety.

Environmental and household considerations

Environmental factors, such as humidity, temperature fluctuations, and exposure to sunlight, can influence the longevity of curtain brackets. Brackets installed in kitchens, bathrooms, or sun-exposed areas may be coated with corrosion-resistant finishes to maintain strength over time. The design must ensure that brackets mounted on surfaces of varying thicknesses remain secure despite environmental stressors, supporting consistent curtain operation and reducing the need for maintenance or replacement.

| Installation Surface | Recommended Bracket Features | Considerations for Varying Thickness |

|---|---|---|

| Thick solid wall (brick, concrete) | Standard brackets, expansion screws | High load-bearing; standard fasteners are sufficient |

| Thin wall (drywall, plasterboard) | Wide base plate, toggle bolts, multiple anchor points | Load distribution critical; reinforcement recommended |

| Wood wall or paneling | Wood screws, adjustable arm brackets | Ensure screws engage solid wood; bracket length may vary |

| Ceiling (plaster, suspended panel) | Toggle bolts, adjustable ceiling brackets | Fasteners must reach structural support; adjust arm length for alignment |

Conclusion on suitability for varying thicknesses

Curtain brackets are designed to accommodate walls and ceilings of different thicknesses through adjustable features, material strength, and versatile anchoring methods. Proper selection of bracket type, fasteners, and design ensures stable and durable installation. By considering load requirements, surface material, and curtain type, brackets can provide long-lasting support while maintaining aesthetic appeal and functional reliability across a wide range of household environments.