Material Composition and Its Influence on the Rusting Tendency of Curtain Rings

The rusting tendency of curtain rings in humid environments is closely related to their material composition, surface treatment, and usage conditions. Curtain rings are commonly made from metal, plastic, wood, or composite materials, and each type responds differently to moisture exposure. Metal options such as iron, steel, or low-grade alloys may react with water vapor when exposed for extended periods, leading to oxidation and the formation of visible rust. This chemical reaction occurs because iron-containing metals bond with oxygen in the presence of moisture, gradually forming iron oxide. Plastic or wooden curtain rings avoid rust formation entirely because they do not contain metal elements, although they may experience other forms of degradation such as swelling or discoloration. Manufacturers often apply electroplating, painting, or powder coating to minimize direct contact between metal surfaces and humid air, helping reduce the risk of rust. The durability of such coatings depends on surface preparation and coating thickness, and any scratches or abrasions may expose the inner metal, increasing the chance of rust in daily household use.

| Common Material | Rust Risk in Humidity | Typical Usage Scenario |

|---|---|---|

| Iron or Steel | High if uncoated; moderate if coated | Living rooms, offices, low-moisture areas |

| Stainless Steel | Low to moderate depending on grade | Bathrooms, kitchens, laundry rooms |

| Plastic | None (no oxidation) | General indoor use, children’s rooms |

| Wood | None, but vulnerable to swelling | Bedrooms, decorative interiors |

Environmental Humidity Levels and Their Impact on Curtain Rings

Humidity plays a direct role in determining whether curtain rings will rust, especially in locations where moisture levels fluctuate throughout the day. Areas such as bathrooms generate steam during showering, which can remain suspended in the air for prolonged periods unless proper ventilation is maintained. When curtain rings made of iron or lower-grade metals are exposed to repeated cycles of condensation and evaporation, the risk of surface oxidation increases. Coastal regions with naturally high humidity also place added pressure on metal products, including curtain accessories. Continuous exposure to ocean breezes containing salt particles accelerates corrosion, making metal curtain rings more susceptible to long-term degradation. Indoor humidity created by humidifiers, laundry drying, or seasonal weather also affects how long metal surfaces remain dry. A relative humidity above 65% generally increases the chance of oxidation, particularly when temperature shifts cause moisture to form on the surface of the curtain rings.

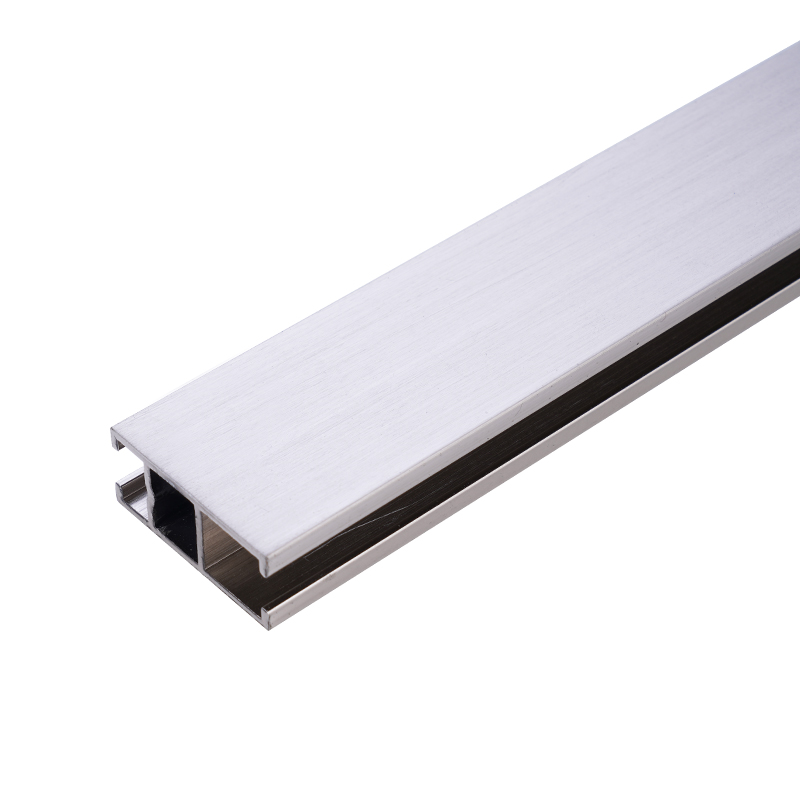

Coating Technologies Used to Protect Curtain Rings from Rust

To reduce rusting in humid settings, manufacturers adopt various surface treatment methods for curtain rings. Electroplating is a widely used technique in which a layer of nickel, chrome, or zinc is deposited onto the metal surface. This forms a barrier that helps prevent moisture contact. Powder coating is another method where polymer powders are baked onto the curtain rings, creating a durable and uniform layer that resists scratching and minor impacts. Painted finishes can also provide some level of moisture protection, although their durability depends on the thickness and quality of the paint. Stainless steel curtain rings generally do not require coatings because the chromium content in stainless steel forms a naturally protective oxide layer. However, if the surface quality is poor or if the steel contains impurities, corrosion may still occur, especially in very humid environments. Surface treatments reduce exposure to moisture, but they cannot provide absolute protection if the coating becomes damaged through friction or repeated movement along curtain rods.

| Coating Method | Protection Level | Suitable for Moist Areas |

|---|---|---|

| Electroplating (Nickel/Chrome) | Moderate to high | Yes if maintained |

| Zinc Coating | Moderate | Moderate |

| Powder Coating | High | Yes, durable for daily use |

| Painted Finish | Variable based on thickness | Suitable for mild humidity |

Daily Usage Factors Influencing the Corrosion of Curtain Rings

The daily operation of curtain rings contributes to their long-term condition in humid environments. When the rings slide along the rod, minor abrasions occur on the coating surface, particularly if the rod material is rough or if dust particles accumulate between the ring and the rod. These microscopic scratches may not be visible to the eye, but over time they expose the underlying metal to humidity. In areas where curtains are opened and closed several times a day, friction gradually wears down protective layers. Additionally, the presence of soap vapor, detergents, and cleaning chemicals in bathrooms can influence oxidation rates. Water droplets left on curtain rings after cleaning or showering also increase the time the surface remains wet, thus supporting the chemical reaction that leads to rust. Households that frequently wash or steam-clean curtains may also notice accelerated wear on the rings due to increased moisture exposure during maintenance activities.

Performance Differences Between Various Types of Metal Curtain Rings

Different metal types behave differently in humid environments. Stainless steel curtain rings are generally regarded as more stable because chromium content forms a passive layer that resists oxidation. However, not all stainless steels perform equally; lower grades may corrode if the moisture contains chlorides or if the surface becomes damaged. Brass and aluminum rings do not rust in the traditional sense because they do not form iron oxide, but they can undergo other types of corrosion such as tarnishing or pitting, which affect their appearance and strength. Iron and untreated steel curtain rings are the most vulnerable to humid conditions, and without coatings, they can show rust within a short time. Manufacturers may blend metals to improve properties, but the quality of the final product still depends on processing conditions and finishing treatments.

| Metal Type | Rust Behavior | Suggested Application |

|---|---|---|

| Stainless Steel | Low risk, good moisture resistance | High humidity areas |

| Aluminum | No rust; may show oxidation marks | General home use |

| Iron/Steel | High risk if uncoated | Dry indoor environments |

Proper Maintenance of Curtain Rings in Humid Environments

Regular maintenance significantly improves the lifespan of curtain rings in moisture-rich settings. Wiping the rings periodically helps remove condensed water, dust, or soap residues that may accelerate corrosion. Using a dry cloth after showering prevents water from collecting on the metal surface. Lubrication with silicone-based products helps decrease friction and reduces coating abrasion during movement along the curtain rod. Cleaning solutions containing harsh chemicals or acids should be avoided because they can damage protective coatings and expose the underlying metal. In high-humidity rooms, good ventilation keeps moisture levels under control, minimizing condensation buildup on curtain rings. A combination of proper material selection and consistent maintenance ensures that the rings maintain their structural stability and visual appearance for an extended period.

Environmental Adaptation and Material Selection for Durable Curtain Rings

Selecting the appropriate material and surface treatment for curtain rings helps ensure long-term performance in humid environments. For bathrooms or kitchens where steam and water exposure are common, stainless steel or powder-coated metal rings offer better resistance than uncoated steel. Households in coastal regions often prefer materials that can handle salt-laden air, making stainless steel and aluminum more suitable options. In areas with moderate humidity, coated iron rings perform reasonably well as long as the coating remains intact. The choice of curtain rods also plays a role because a smooth rod reduces friction and slows the wearing process. Understanding the environmental conditions and selecting materials that fit those requirements allow curtain rings to remain functional and visually consistent throughout everyday usage cycles.