Understanding the Functional Role of Curtain Rod Connectors

Curtain rod connectors serve as structural components that link two or more rod sections into a longer and continuous support system. Their primary function is to reinforce the connection between rods, distribute weight across the extended structure, and maintain alignment. When considering their suitability for mixing lightweight sheer curtains with heavy fabric curtains, it is necessary to evaluate how connectors respond to variations in fabric weight, movement, and tension. Since connectors are not singular load-bearing tools but part of a larger assembly, their performance depends on the rod material, installation quality, bracket spacing, and the total combined weight of the curtains. Understanding their role helps determine whether they can adequately support a mixed-curtain configuration without bending, sagging, or loosening during use.

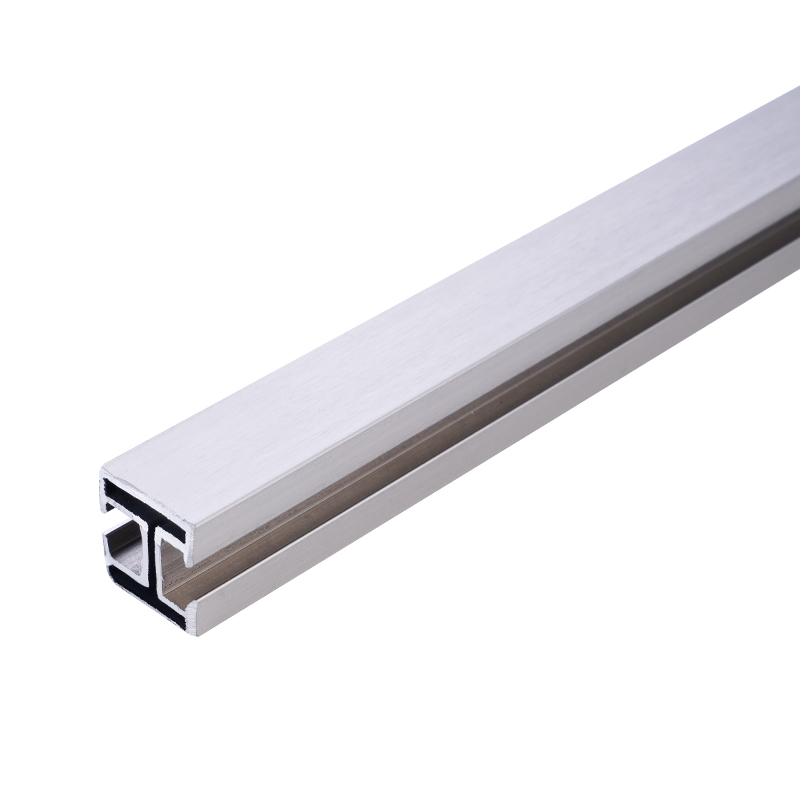

Material Characteristics of Curtain Rod Connectors

The materials used for curtain rod connectors influence their strength, resilience, and ability to handle the different loads that arise from mixing fabrics of various weights. Connectors made from steel, aluminum, or solid brass generally provide higher structural stability compared to connectors made from lightweight plastic or hollow alloys. When combining sheer curtains with heavier drapes, connectors must maintain rigidity and resist deformation across the central rod joint. In environments with frequent curtain movement, such as areas exposed to drafts or frequent opening and closing, stronger materials contribute to long-term stability and smooth rod performance. The chosen connector must also be compatible with the rod material to prevent looseness or uneven stress transfer.

Load Distribution When Mixing Sheer and Heavy Curtains

One of the key considerations when mixing lightweight and heavy curtains is the way load is distributed along the rod and, consequently, across the connector. Heavy curtains place downward force on the rod, while sheer curtains add minimal load. This imbalance can create uneven pressure at the connection point if the rod extends over a long span or if brackets are spaced too far apart. To maintain stability, connectors should be part of an assembly that includes adequate bracketing and a rod with sufficient wall thickness. When supported correctly, connectors can help maintain rod alignment and reduce stress concentration, allowing the system to hold both fabric types without tilting or premature fatigue.

Impact of Rod Diameter and Wall Thickness on Connector Suitability

The diameter and wall thickness of the curtain rod significantly influence how well the connector performs when supporting mixed curtains. A larger diameter offers improved stiffness and reduces the chance of bending around the connector joint. Thicker walls also enhance the rod’s ability to distribute the weight of heavy curtains without relying solely on the connector for reinforcement. Connectors designed specifically for thicker rods typically provide more secure engagement, which helps maintain stability. Therefore, when mixing lightweight and heavy curtains, selecting a rod and connector combination with appropriate thickness and diameter is essential for ensuring safe and reliable use.

Bracket Placement to Support Connectors

Bracket placement plays a crucial role in supporting curtain rod connectors, especially when heavy curtains are paired with lighter ones. If brackets are installed too far apart, the connector becomes a stress point and may experience bending forces. Installing a support bracket near or directly under the connector can greatly improve load distribution and prevent sagging. This approach ensures the connector acts as a stabilizing element rather than the primary load carrier. With proper bracket positioning, connectors can support mixed curtain setups effectively and reduce the risk of warping or joint separation.

Comparison of Connector Types and Their Performance

Different types of curtain rod connectors exhibit unique performance characteristics when used with varying curtain weights. Straight connectors help extend the rod across long spans, while adjustable connectors allow for flexible sizing. Reinforced connectors are designed to offer additional structural stability and may be more suitable for mixed-weight curtain installations. The table below highlights general distinctions among common connector categories to support selection decisions.

| Connector Type | Structural Strength | Suitability for Mixed Curtains | Typical Application |

| Straight Metal Connector | Moderate to High | Suitable for most setups with proper bracketing | Extending standard rods |

| Reinforced Heavy-Duty Connector | High | Highly suitable for heavy and mixed curtain combinations | Large windows and thick fabric installations |

| Plastic Lightweight Connector | Low to Moderate | Less suitable for heavy curtain mixing | Light curtains and decorative rods |

| Adjustable Extension Connector | Moderate | Suitable only when heavy curtains are limited in weight | Temporary or flexible setups |

Tension, Movement, and Long-Term Connector Stability

Daily use of curtains involves tension and repeated movement, especially when one side carries significantly more weight than the other. In mixed setups, heavy curtains generate more friction along the rod, which can cause connectors to loosen over time if the rod is not secured properly. Metal connectors generally provide better resistance to long-term movement, while plastic connectors may gradually lose grip. Ensuring that the rod ends are fully inserted into the connector and tightening any fastening screws helps maintain stability. The choice of curtain rings or gliders also affects movement and friction, indirectly influencing connector performance.

Environmental Factors Affecting Connector Durability

Environmental conditions such as humidity, temperature variation, and exposure to sunlight can affect the durability of connectors, especially when rods are installed near windows or in rooms like bathrooms. Metal connectors may resist environmental wear more effectively than plastic ones, although corrosion-resistant coatings can further enhance longevity. When heavy curtains are installed in humid environments, the connector must withstand repeated exposure to moisture without weakening. The compatibility between rod and connector materials also determines how well the system maintains alignment despite environmental changes.

Installation Practices for Safe Mixing of Curtain Types

Proper installation is essential when using connectors to support mixed lightweight and heavy curtains. Ensuring that rods and connectors are securely aligned and fitted prevents wobbling and reduces stress on the joint. Brackets should be installed level and firmly secured to the wall or ceiling. In cases where heavy curtains are significantly heavier than the sheer curtains, adding an additional central bracket near the connector can enhance stability. Professional installation can be helpful for large windows or complex setups, ensuring that the connector and rod system safely support fabric variations.

Situations Where Connectors Are Not Recommended

Although connectors can effectively support mixed curtain types, certain situations may indicate caution. Extremely heavy fabric curtains may exceed the load capacity of a multi-part rod, even with connectors and reinforcement. Long window spans without adequate bracket support can create bending stress that the connector cannot fully compensate for. In such situations, a single-piece heavy-duty rod may be more appropriate. However, for general home use where curtain weights are moderate, connectors typically perform adequately when complemented with careful installation and appropriate hardware selection.

Examples of Load Ratings for Connectors and Rods

Manufacturers often provide load ratings for rods and connectors, helping users determine whether the combination can support mixed curtain types. The following table provides general reference values that illustrate how load variation influences connector selection.

| Rod/Connector Material | Approximate Load Capacity | Fabric Mixing Suitability |

| Steel Rod + Reinforced Connector | High load capacity suitable for heavy drapes | Suitable for mixing lightweight and heavy curtains |

| Aluminum Rod + Standard Connector | Moderate load capacity | Suitable for balanced fabric combinations |

| Plastic Rod + Plastic Connector | Low load capacity | Limited suitability for mixed curtain weights |

Practical Considerations for Mixing Fabric Types

Mixing lightweight sheer curtains with heavy fabric curtains offers visual layering and customizable light control, making this combination popular in interior design. Curtain rod connectors can support this pairing when the rod assembly is planned with attention to material strength, bracket positioning, and load balance. Ensuring that the heavier curtain panel is positioned near a bracket reduces pressure on the connector. Additionally, choosing curtain rings or hooks that glide smoothly helps minimize stress from daily operations. With thoughtful planning, connectors complement mixed curtain arrangements and maintain a stable and functional window treatment system.