Analysis of the difference between handmade and machining curtain finals

As an important part of the overall shape of curtains, Curtain finals not only have a decorative effect, but also reflect the style and taste of the home space. In the actual production process, curtain finals mainly have two methods: handmade and machining. These two production methods have their own characteristics in terms of craftsmanship, style, applicability and cost. Understanding the differences between them will help consumers make more reasonable choices based on their own needs.

Differences between process details and expressiveness

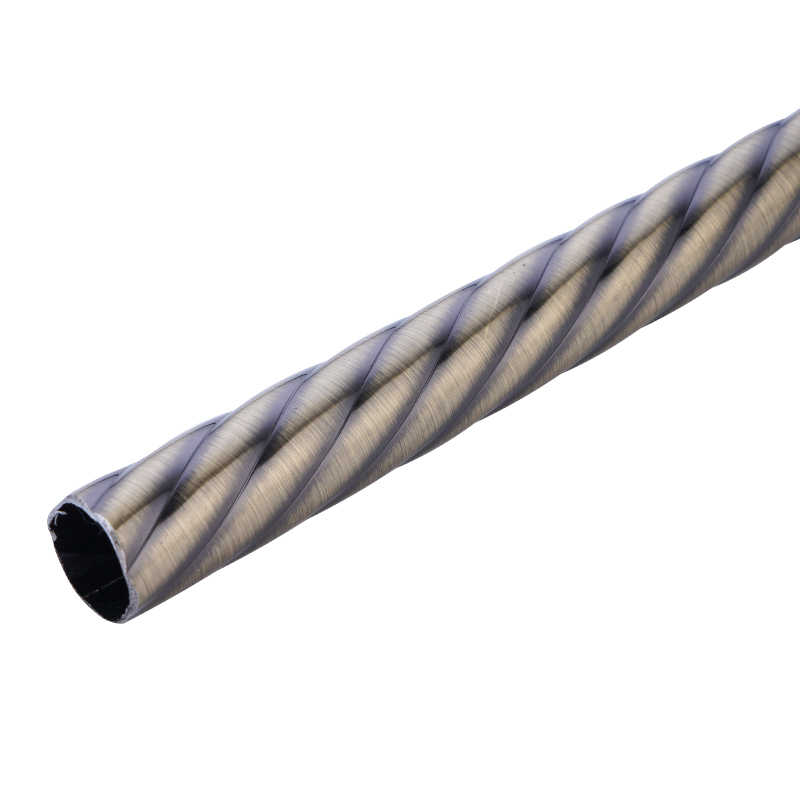

Handmade curtain finals are more refined in process processing and are usually done by experienced craftsmen. Each carving, polishing, and decorative edge treatment can be fine-tuned according to the material characteristics and design style. Especially in personalized customization, handmade craftsmanship can reflect more unique styles and artistic expressions, such as wood patchwork, carving, inlay and other details, which are more flexible, and are suitable for spaces that need to highlight the aesthetics of handcrafts and traditional charm.

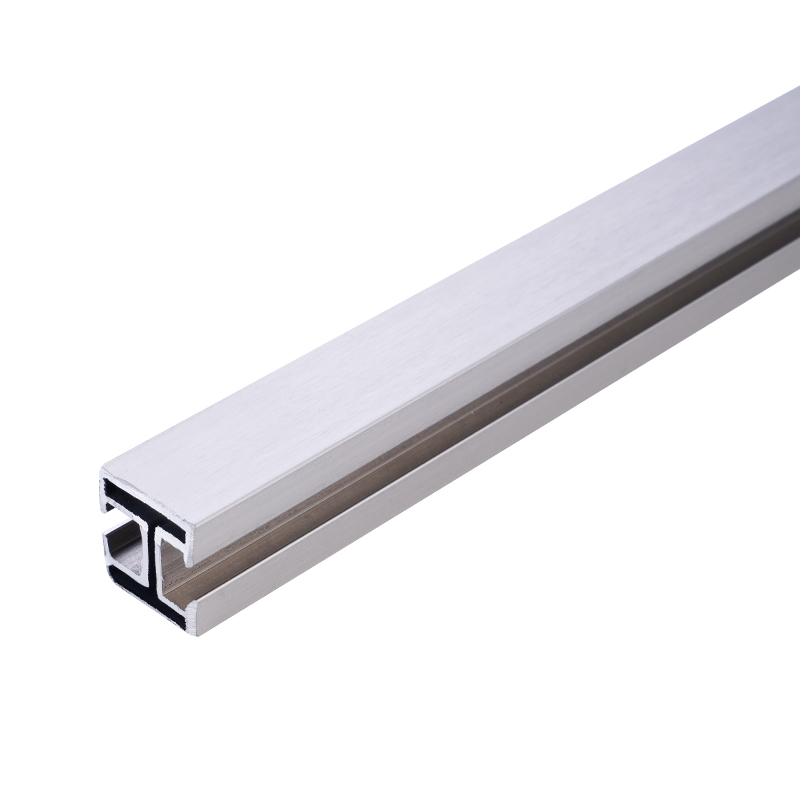

In contrast, machining curtain finals rely on the standardized process of mechanical equipment, focusing on efficiency and consistency. Machine operation can quickly complete mass production, suitable for application scenarios with standard specifications and unified styles. For example, in projects such as hotels, offices or apartments, machining curtain finals facilitates unified style, batch procurement, and saves time and costs. Although the details are not as flexible as manual processing, the overall shape is clean and neat, which is suitable for space design that pursues simplicity.

Comparison of style and design flexibility

Handmade is more suitable for the design of curtain finals with diverse styles and rich variations. Craftsmen can adjust according to different decorative styles, such as carving patterns, paint treatment and other detailed designs in retro, Chinese, French and other styles, which usually require manual completion. Especially in high-end homes, customized villas and other projects, handmade curtain finals can create a unique and warm atmosphere.

The machining curtain finals are more suitable for modern, simple, industrial style and other styles that pursue regular lines and functional styles. Design styles are often set by programs and are highly repeatable, but they are slightly limited in terms of creativity and uniqueness. Although some equipment can currently achieve surface texture or decoration, it is still less than the freedom brought by hand.

The difference between applicable scenarios and user experience

From the perspective of applicability, handmade curtain finals are suitable for places that focus on beauty and atmosphere creation, such as family homes, boutique homestays, high-end clubs, etc. This type of place has higher requirements for the decorativeness of curtain parts, and the presence of manual details can enhance the overall space texture. Handmade curtain finals are also more adaptable when dealing with irregular rods and special track structures.

Machining curtain finals are more suitable for occasions where there are requirements for cost, construction period and uniformity, such as commercial buildings, rental apartments and school dormitories. The unified style, neat lines and relatively low production costs make it more practical. Although it is not as expressive as manual, its convenience and efficiency show obvious advantages in large-scale use.

Cost and time considerations

In terms of cost, handmade production is time-consuming and labor-intensive, and has high requirements for process requirements, so it is relatively costly, making it suitable for consumers with sufficient budget and pursuing details. Due to the efficient operation of equipment and low labor costs, the overall price is more affordable. For projects with tight time, machining also has more operational advantages.

In terms of time arrangement, hand-made production often takes longer cycles, especially when it involves complex processes or personalized patterns, which require more time to proofread and adjust. Machining can achieve rapid sample production and mass production, which is more suitable for emergency construction periods.

Handmade and machined curtain finals have advantages in terms of technology, style, application scenarios and costs. The former emphasizes details and artistic expression, which is suitable for places that pursue beauty and personality; the latter focuses on efficiency and unity, and is more suitable for environments with strong functional needs. Which method to choose must be comprehensively considered based on the actual spatial style, budget arrangement and project nature.