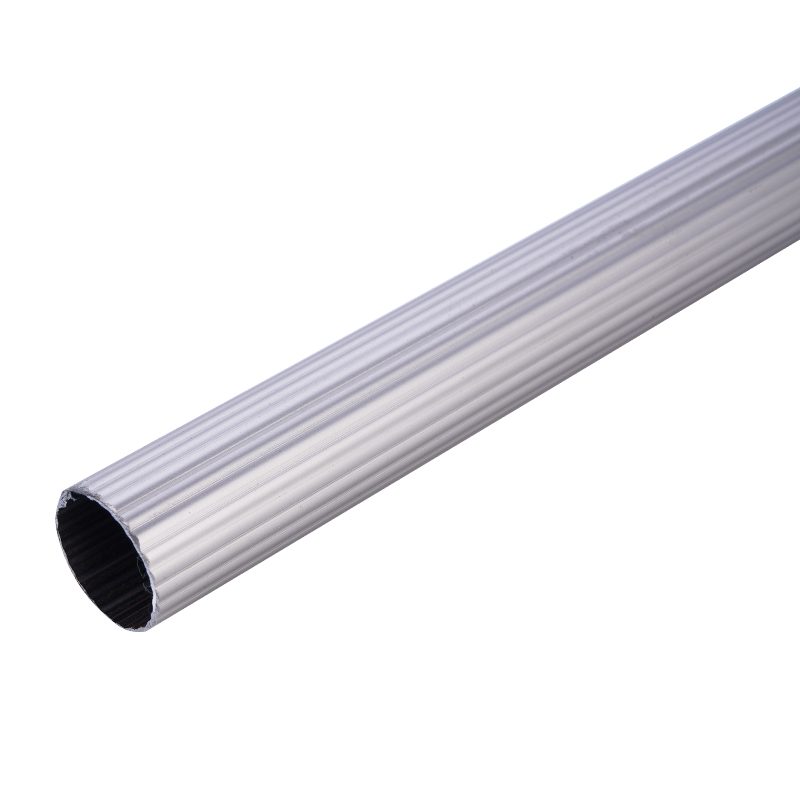

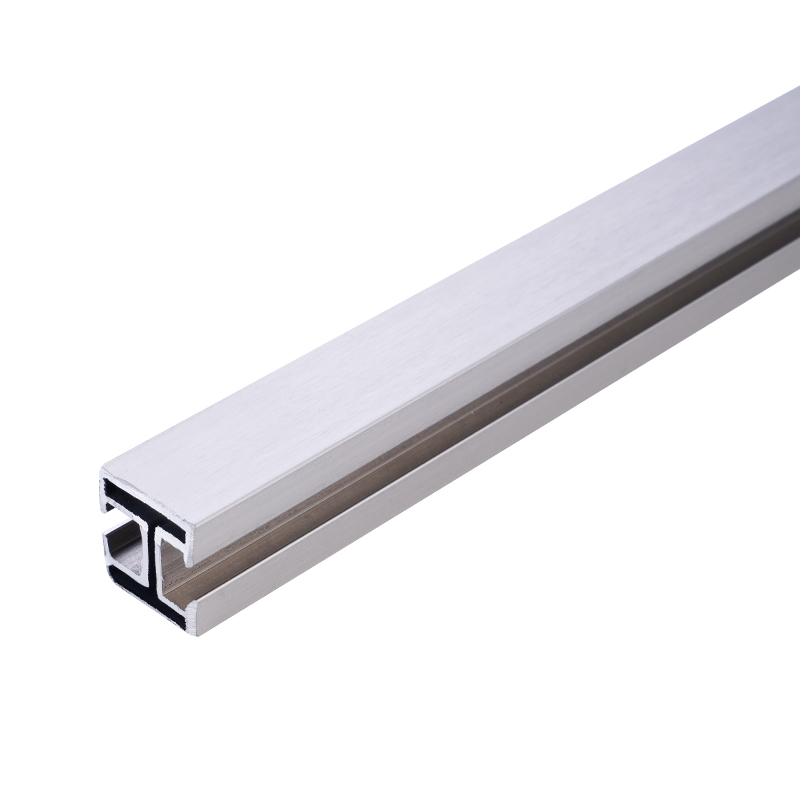

As an important component connecting curtains with the indoor environment, the load-bearing capacity of curtain ceiling brackets is directly related to the normal use and overall safety of curtains. The material selection of curtain ceiling brackets is a key factor in ensuring load-bearing capacity. High-strength metal materials are usually widely used in the manufacturing process of brackets. These materials have advantages in structural strength and toughness, can withstand large tension and pressure, and avoid deformation or breakage of brackets due to excessive weight. The processing technology of materials is equally important. Reasonable heat treatment and surface treatment not only enhance the mechanical properties of the bracket, but also improve its durability and corrosion resistance, thereby ensuring long-term and stable load-bearing performance.

The structural design of the bracket directly affects the load-bearing effect. Reasonable design will consider the distribution of force, so that gravity is evenly transmitted to the support surface, avoiding concentrated stress and causing local damage. The addition of multi-point support and reinforcement can effectively improve the overall load-bearing capacity. At the same time, the design will focus on the close combination of the bracket and the ceiling, and reduce the shaking or looseness caused by use through a stable installation method. This not only extends the service life of the bracket, but also ensures the safe hanging of the curtain.

The installation method of the curtain ceiling bracket has a significant impact on the load-bearing performance. Professional installation steps include accurate positioning and the use of appropriate fixings to ensure that the bracket is firmly fixed to the ceiling. Improper installation, such as inappropriate selection of fixings or position deviation, may lead to reduced bearing capacity and even safety hazards. Therefore, reasonable installation guidance and technical support are essential to ensure the bearing capacity of the bracket.

For application scenarios with heavy fabrics or multi-layer curtains, the bearing capacity of the bracket needs to meet higher standards. Multi-layer curtains are often heavier than single-layer curtains, and they are pulled frequently during use, which places higher demands on the durability of the bracket. The bracket must not only withstand static loads, but also cope with dynamic load changes to maintain structural stability. These factors need to be considered comprehensively in design and material selection to ensure that the bracket can adapt to the actual use environment and avoid problems such as sagging, deformation or falling off.

The maintenance of curtain ceiling brackets should not be ignored. Regularly checking the connection status and load-bearing components of the bracket can timely detect potential hidden dangers, such as loose screws or worn components. Reasonable maintenance measures can extend the service life of the bracket and ensure that the curtains are safely hung for a long time.

The good bearing capacity of curtain ceiling brackets is the result of the combined effect of many factors. From material selection to structural design, from installation process to later maintenance, every link affects the final load-bearing performance. Only by strictly controlling every link can we ensure that the bracket can stably support heavy fabrics and multi-layer curtains and meet the user's needs for safety and user experience. Such a bracket not only improves the functionality of the curtains, but also adds reliable protection to the overall indoor environment.