Introduction to Curtain Hooks and Their Functional Requirements

Curtain hooks are small but essential components in window treatment systems, providing the connection between curtain panels and rods or tracks. Their effectiveness relies on a combination of material durability, mechanical strength, and resistance to environmental factors such as moisture or air pollutants. Assessing whether curtain hooks are rustproof, corrosion-resistant, and wear-resistant involves evaluating the materials used, manufacturing processes, and long-term usage conditions.

Common Materials for Curtain Hooks

Curtain hooks are typically made from metals such as stainless steel, brass, or aluminum, or from reinforced plastics. Each material has inherent properties that influence corrosion and wear resistance. Stainless steel contains chromium, which forms a passive oxide layer protecting against rust. Brass is naturally resistant to corrosion in humid environments. Aluminum is lightweight and forms a thin oxide layer that limits surface degradation. Plastic hooks are often reinforced with additives to improve strength and reduce wear.

Rust and Corrosion Resistance Mechanisms

Metal curtain hooks rely on surface chemistry and protective coatings to resist rust and corrosion. Stainless steel’s oxide layer shields the metal from oxygen and moisture, while brass resists oxidation due to its copper content. Additional surface treatments, such as electroplating or powder coating, further enhance resistance by creating a barrier against air, water, and chemicals. Plastic hooks are inherently resistant to rust, although exposure to UV light or chemicals can slowly degrade their surface over time.

Wear Resistance and Mechanical Durability

Wear resistance refers to the ability of curtain hooks to withstand repeated sliding, pulling, or rubbing against rods, tracks, or curtain fabrics. Metal hooks generally perform well under repeated mechanical stress, maintaining shape and function for long periods. Plastic hooks with reinforced fillers or high-quality polymers are also designed to resist abrasion and maintain their mechanical integrity. Lower-quality plastic or thin metal hooks may show deformation or wear if subjected to continuous heavy use.

Factors Affecting Long-Term Hook Deformation

Deformation of curtain hooks can occur due to prolonged mechanical stress, overloading, or exposure to temperature extremes. Hooks that carry heavier curtains or are constantly pulled may bend or lose their original shape. Similarly, exposure to high heat or cold can change the flexibility of metals or plastics, influencing their long-term dimensional stability. Selecting hooks with appropriate load ratings and material strength reduces the likelihood of permanent deformation.

Influence of Environmental Conditions

Environmental factors such as humidity, airborne pollutants, and cleaning agents impact the longevity of curtain hooks. High humidity can accelerate corrosion in unprotected metal hooks, while exposure to acidic or alkaline cleaning solutions can degrade coatings. Even though stainless steel and brass offer high resistance, maintaining clean and dry conditions further prolongs lifespan. Plastic hooks are generally unaffected by moisture but may gradually weaken if exposed to strong sunlight or chemical cleaners over long periods.

Comparison of Hook Material Performance

| Material | Rust Resistance | Corrosion Resistance | Wear Resistance | Deformation Risk |

| Stainless Steel | High | High | High | Low under normal load |

| Brass | Moderate | High | Moderate to high | Low to moderate depending on load |

| Aluminum | Moderate | Moderate | Moderate | Moderate under heavy load |

| Reinforced Plastic | Not applicable | High | Moderate to high | Low under recommended load |

Impact of Load and Curtain Type

The type and weight of curtains directly influence the performance of hooks. Lightweight curtains exert minimal stress, allowing hooks to maintain shape and function for extended periods. Heavier drapes or multi-layered fabrics increase stress on the hook points, requiring stronger materials and potentially more frequent inspections to ensure continued safety. Proper load distribution across multiple hooks reduces localized stress and deformation risk.

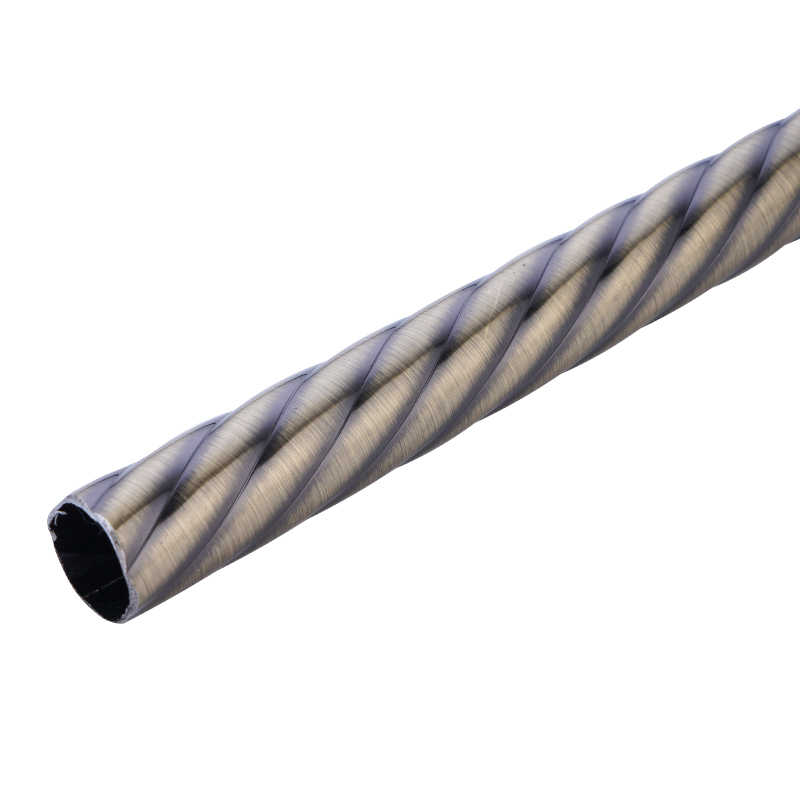

Manufacturing Quality and Surface Treatment

High-quality manufacturing processes contribute to hook durability. Metal hooks that undergo precise forming, deburring, and coating processes show better resistance to corrosion and mechanical wear. Plastic hooks produced with uniform molding and reinforced fillers exhibit fewer stress points and are less prone to cracking. Surface treatments, including powder coating, nickel plating, or anodizing, further enhance performance by providing an additional barrier to environmental factors.

Installation Considerations Affecting Longevity

Proper installation is key to ensuring that hooks function safely over time. Hooks must be appropriately spaced along the rod or track and secured according to manufacturer recommendations. Over-tightening or uneven spacing can create points of excessive stress, increasing the risk of bending or breakage. Installation tools and techniques, as well as alignment with curtain weight, influence long-term hook performance.

Maintenance Practices to Prevent Degradation

Routine maintenance helps maintain rustproof, corrosion-resistant, and wear-resistant properties. Cleaning hooks with mild solutions, avoiding abrasive chemicals, and checking for loosening or bending contribute to long-term stability. Periodic inspection of hooks supporting heavier curtains or those in humid environments helps detect early signs of wear or corrosion, allowing timely replacement if needed.

Plastic vs. Metal Hooks in High-Moisture Environments

In kitchens, bathrooms, or other high-humidity areas, plastic hooks are often preferred due to their immunity to rust. Metal hooks with protective coatings can also perform well, but surface damage or coating wear may expose underlying metal to corrosion. Selection of materials compatible with the environment ensures that hooks maintain structural integrity over years of use.

Performance Under Frequent Use

Curtain hooks that are frequently handled, removed, or adjusted are exposed to higher mechanical wear. Metal hooks tend to retain shape but may develop minor scratches or coating wear, while plastic hooks can experience slight surface abrasion. Reinforced or coated hooks are better suited for high-use scenarios. Consistent monitoring and occasional replacement help maintain safety and appearance.

Design Features Enhancing Durability

Curved or rounded hooks reduce stress concentration points, lowering the likelihood of deformation. Hooks with thicker cross-sections or integrated reinforcements distribute loads more evenly. Surface treatments or polymer additives increase resistance to chemical exposure, wear, and UV degradation. Thoughtful design in combination with material selection extends the functional life of curtain hooks.

Long-Term Observations and Practical Use

Long-term usage of curtain hooks generally shows that well-selected materials and proper installation prevent major issues. Rustproof and corrosion-resistant hooks maintain structural integrity in most environments, while wear-resistant designs sustain repeated curtain movement. Deformation or breakage is uncommon when weight limits are respected and maintenance is performed periodically.