How to Determine the Quality and Load-Bearing Capacity of Curtain Rods

Curtain rods play a vital role in the functionality and aesthetics of a space. They serve as the support structure for curtains, ensuring that they are hung securely while adding to the overall design of the room. However, when selecting a curtain rod, it is important to evaluate its quality and load-bearing capacity to ensure that it will adequately support the weight of the curtains without bending, warping, or becoming damaged. This article will explore how to determine the quality and load-bearing capacity of curtain rods by considering factors such as materials, design, size, installation, and maintenance practices.

Understanding the Load-Bearing Capacity of Curtain Rods

The load-bearing capacity of a curtain rod refers to its ability to support the weight of the curtains and any additional elements, such as tiebacks, valances, or decorative accessories, without bending, warping, or becoming detached from the wall. The capacity is influenced by various factors, including the rod material, diameter, length, wall mounts, and the number of support brackets used. In order to select a curtain rod that can adequately support the curtains, it is essential to understand how these factors contribute to the overall strength of the system.

1. Material of the Curtain Rod

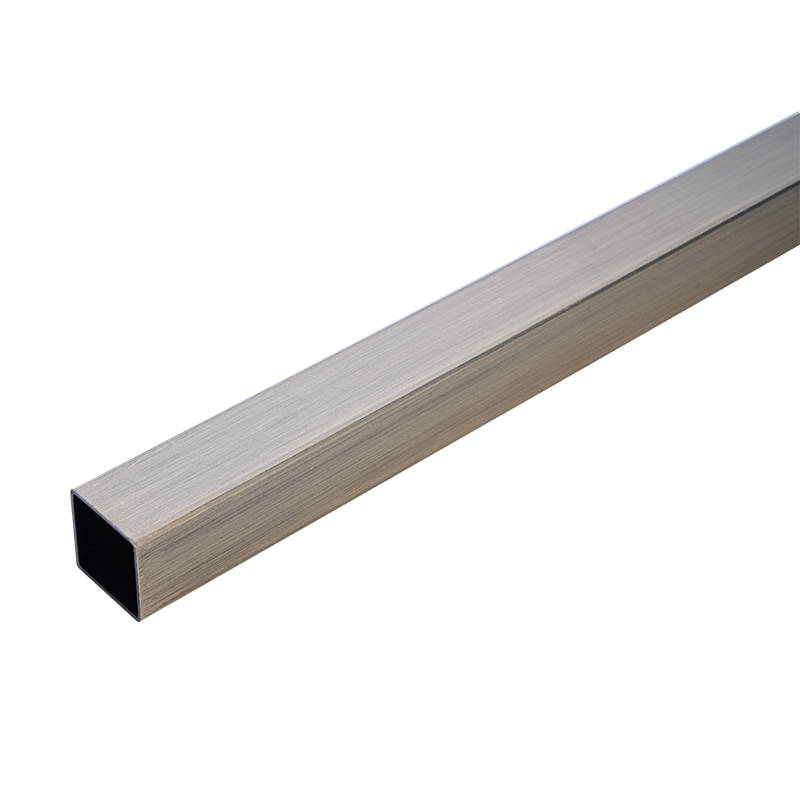

The material of the curtain rod is one of the most important factors when determining its load-bearing capacity. Different materials have varying levels of strength, weight tolerance, and durability, which can significantly affect the rod's ability to support heavy curtains. Common materials used for curtain rods include wood, metal, and plastic, each of which has unique characteristics that influence its performance.

Metal curtain rods, typically made from materials such as steel, aluminum, or wrought iron, are generally stronger than wood or plastic rods. Steel rods, in particular, offer high tensile strength, making them ideal for supporting heavier curtains, such as those made from thick fabrics or multiple layers. Aluminum rods are lightweight and resistant to corrosion, but they may not support as much weight as steel. Wrought iron rods, while heavier, offer excellent strength and durability, making them suitable for larger windows or heavier curtain materials.

Wooden curtain rods can add a rustic or traditional touch to a room, but their load-bearing capacity tends to be lower than that of metal rods. The quality of the wood, its density, and the manufacturing process all contribute to the strength of the rod. Solid hardwoods such as oak or mahogany are stronger than softer woods like pine or MDF (medium-density fiberboard), which may not be as durable under heavy loads.

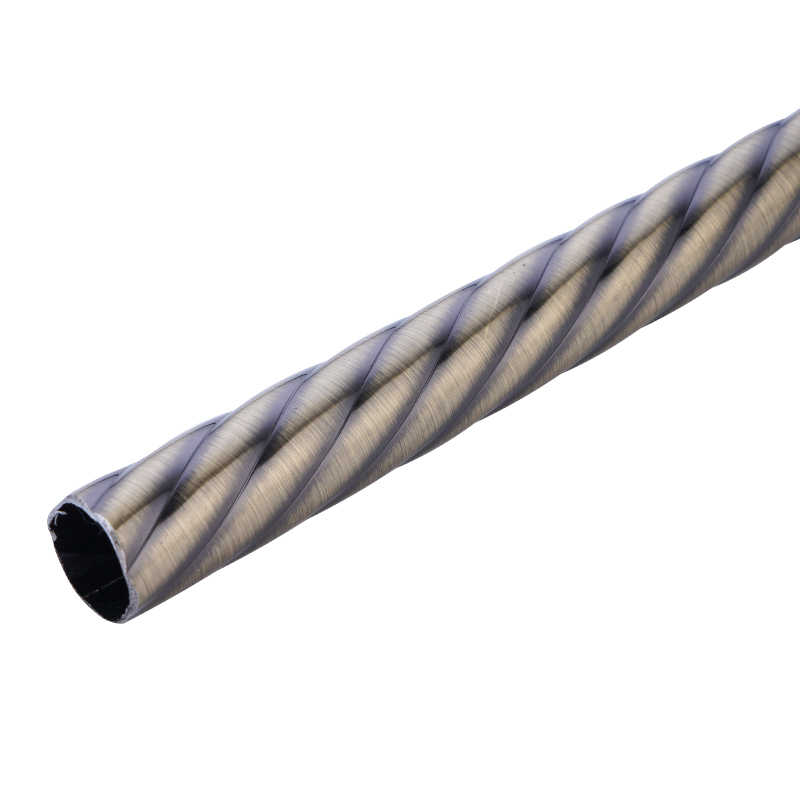

2. Diameter of the Curtain Rod

The diameter of the curtain rod plays a crucial role in determining its load-bearing capacity. A larger diameter generally provides greater strength and stability, allowing the rod to support more weight without bowing or bending. For example, a curtain rod with a diameter of 1 inch may be suitable for lightweight curtains, while a rod with a diameter of 1.5 inches or more may be necessary for heavier curtains or drapes.

The thickness of the curtain rod can also affect its flexibility. A thicker rod is less likely to flex or bend under the weight of heavy curtains, which helps maintain the appearance of the curtains and prevents the rod from becoming deformed over time. On the other hand, rods with smaller diameters may not provide sufficient support for heavier fabrics, leading to potential sagging or breakage.

3. Length of the Curtain Rod

The length of the curtain rod is another factor that impacts its load-bearing capacity. As the length of the rod increases, so does the amount of stress it will endure when supporting the weight of the curtains. A longer rod will require additional support brackets to ensure that it remains stable and does not sag or bend. The more support brackets used, the more evenly the weight is distributed along the length of the rod, which can help prevent the rod from becoming overloaded.

For standard window sizes, a curtain rod that spans 5 to 6 feet may not need additional support, but for larger windows or wide doors, a rod that extends beyond 8 feet will require multiple support brackets to distribute the load evenly. When purchasing a curtain rod, it is important to ensure that the length is suitable for the window or space while also factoring in the weight of the curtains being used.

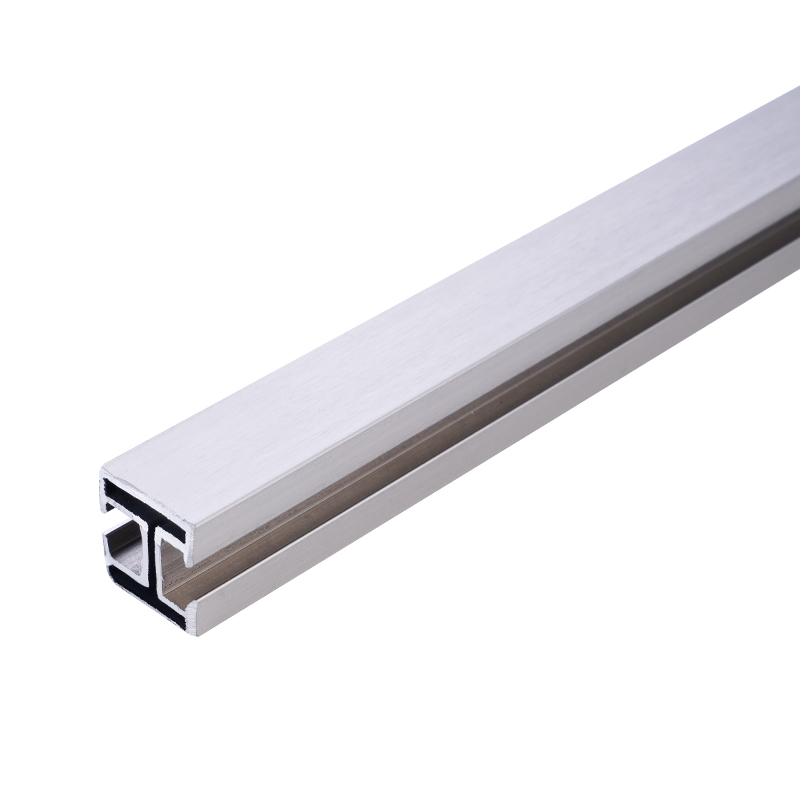

4. Support Brackets and Installation

The support brackets and the method of installation are essential considerations for ensuring the stability of the curtain rod. The load-bearing capacity of the curtain rod is not solely dependent on the rod itself, but also on the strength of the wall mounts and support brackets. Brackets that are made from sturdy metal, such as steel or wrought iron, provide better support compared to plastic or lightweight materials.

The number of support brackets used should correspond to the length of the rod. A general rule of thumb is to use one bracket for every 3 to 4 feet of rod length, especially for longer rods. For particularly heavy curtains, additional brackets may be necessary to ensure that the rod remains level and stable. The brackets should also be securely fastened to the wall using appropriate anchors, especially if the wall is made of drywall or other materials that may not support the weight of the curtains alone.

It is important to follow the manufacturer's recommendations for installation to ensure that the curtain rod is properly supported. Inadequate installation can lead to the rod becoming detached from the wall or sagging under the weight of the curtains, which can cause damage to both the rod and the curtains.

5. Curtain Weight

The weight of the curtains themselves plays a major role in determining the required load-bearing capacity of the curtain rod. Lighter fabrics, such as sheer curtains or lightweight cotton, do not exert as much pressure on the rod, allowing for the use of smaller-diameter rods or rods made from less durable materials. On the other hand, heavier fabrics like velvet, blackout curtains, or thermal drapes require a stronger rod to ensure that they are properly supported.

It is important to match the weight of the curtains to the appropriate curtain rod material, diameter, and length. Manufacturers often provide guidelines regarding the maximum weight that a curtain rod can support, which can help consumers select the right rod for their needs. If there is any doubt about the suitability of a particular rod, it is better to choose a rod with a higher load-bearing capacity to prevent issues such as bending or warping.

6. Maintenance and Care

To ensure that the curtain rod continues to perform well over time, regular maintenance and care are necessary. Cleaning the rod and brackets periodically to remove dust, dirt, and debris can help maintain their appearance and prevent the buildup of corrosive materials that could weaken the rod or the support brackets. For metal rods, it may be necessary to apply a rust-resistant coating or paint to prevent corrosion, especially in areas with high humidity.

Inspecting the rod and support brackets regularly for signs of wear or damage is also important. If the rod starts to bend or show signs of weakness, it should be replaced or reinforced with additional brackets. Ensuring that the curtain rod is properly aligned and level will help prevent unnecessary stress on the rod and extend its lifespan.