Basic concept of curtain finials safety

As an important part of curtain decoration, curtain finials not only play the role of beautifying space, but also its safety is the focus of users' attention. The safety of curtain finials is mainly reflected in structural stability, installation firmness and the safety of materials used. Structural stability ensures that the top decoration is not easy to loosen or deform in daily use, and installation firmness is related to whether the top decoration can be safely fixed on the wall or window frame to avoid falling accidents. The safety of materials involves whether the materials used for the top decoration meet environmental protection standards and whether there are flammable or toxic components. These factors directly affect the safety of the use environment.

Risk factors of curtain finials falling

The risk of curtain finials falling mainly comes from improper installation, material quality problems and aging caused by long-term use. Improper installation may include unreasonable selection of fixings, wrong selection of installation location or non-standard construction process, resulting in insufficient bearing capacity of the top decoration and falling off. Top decorations with substandard material quality are prone to breakage or deformation when subjected to gravity or external force, thus causing safety hazards. In addition, long-term exposure to environmental conditions such as sunlight and moisture may cause some materials to age and crack, further increasing the risk of falling. Therefore, in the process of purchasing and installing the top decoration, special attention should be paid to these risk factors and corresponding measures should be taken to prevent them.

Common causes of curtain finials damage

Damage of curtain finials is mainly manifested in the shedding of surface coating, structural deformation and loose connection parts. The shedding of surface coating is often caused by improper material selection or long-term contact with water vapor and dust, which affects the beauty and protective effect of the top decoration. Structural deformation may be caused by design defects of the top decoration itself or external force extrusion, such as excessive force when handling or cleaning. Loose connection parts are mostly caused by improper use of screws, nails or adhesives during installation, which become loose over time. Timely detection and treatment of these damage problems are of great significance to ensure the safe use of curtain finials.

The role of installation specifications in ensuring safety

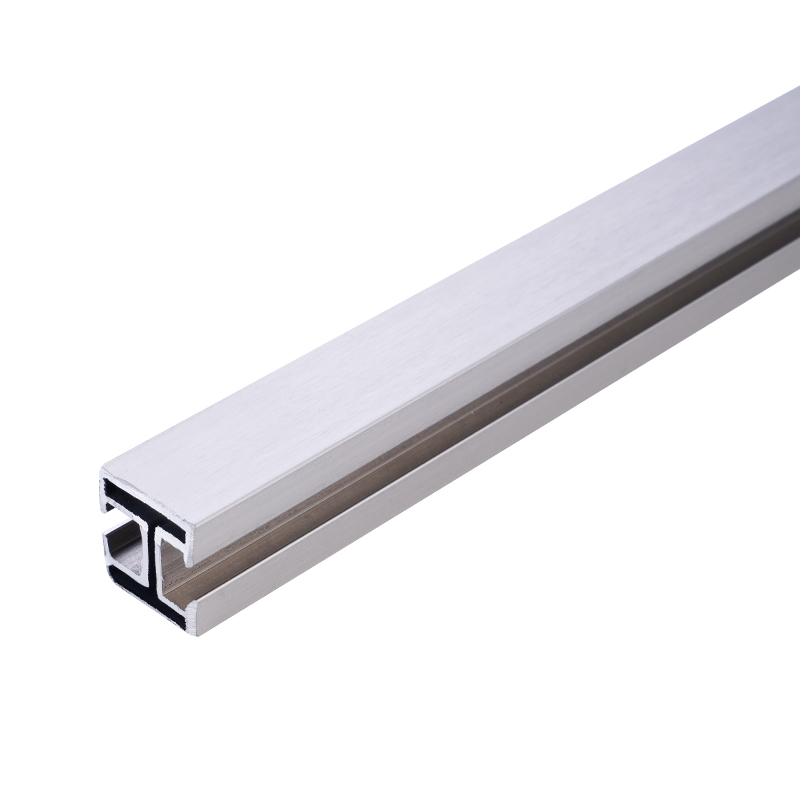

Correct installation specifications are an important prerequisite for ensuring the safety of curtain finials. During installation, appropriate fixings should be selected according to the material and weight of the ceiling, such as expansion bolts, special hooks, etc., and ensure that the wall or window frame has sufficient bearing capacity. The installer must perform construction in accordance with the design requirements and operating procedures to avoid unstable or loose ceiling positions due to installation errors. In addition, the installation environment should be kept dry and clean to prevent moisture from affecting the performance of the fixing materials. Compliance with installation specifications not only reduces the risk of falling, but also extends the service life of the ceiling.

Impact of material selection on safety

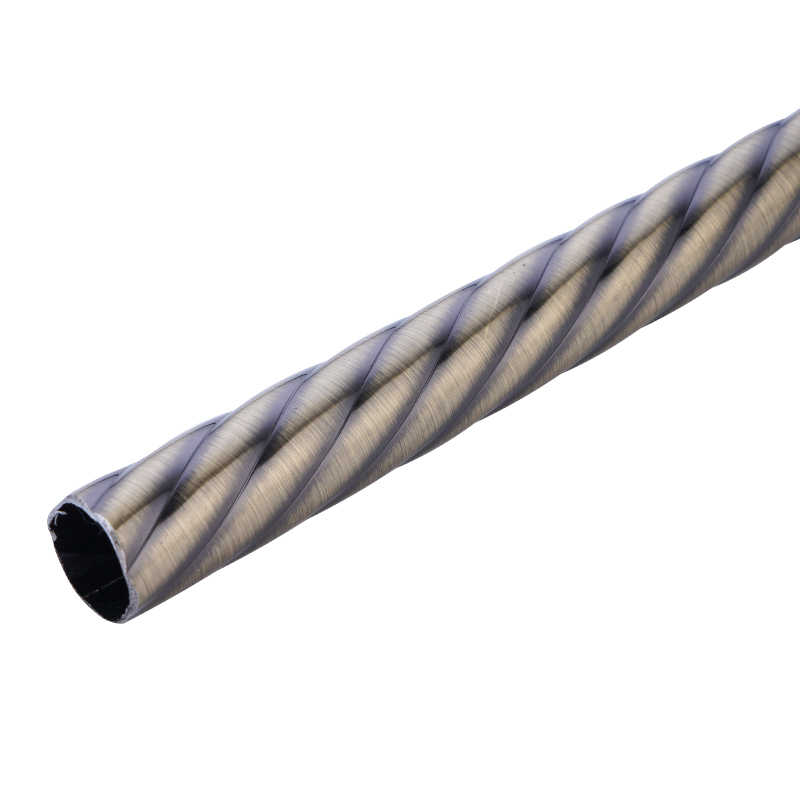

Curtain finials are made of a variety of materials, including wood, metal, plastic, fabric, etc., and each material has different safety performance. Wooden ceilings have a hard texture and strong structural stability, but they are easily deformed by moisture, so moisture-proof treatment is required. Metal ceilings are hard and durable, but some metal surfaces may have sharp edges, so protection is required during installation and use. Plastic ceilings are light and low-cost, but some low-quality plastics are brittle and lack durability. Fabric ceilings are beautiful and soft, but they need to be cleaned regularly and are prone to moisture and mold. Reasonable selection of materials and combination with the actual use environment can help improve the safety of curtain finials.

The significance of daily maintenance in preventing damage

The safety of curtain finials is closely related to its daily maintenance. Regular cleaning can prevent dust accumulation and material aging. At the same time, pay attention to the use of appropriate cleaning tools and formulations to avoid damage to the surface coating and structure. Regularly check the fixings. If they are loose or corroded, they should be reinforced or replaced in time to prevent the top decoration from falling due to loose fixation. For wooden or metal top decorations, attention should be paid to moisture and rust prevention to delay material deterioration. Good maintenance habits can effectively extend the service life of curtain finials and reduce safety hazards.

The impact of the use environment on the safety of top decorations

The use environment of curtain finials has a direct impact on its safety. High humidity environment can easily cause wooden top decorations to expand and deform and metal parts to rust, increasing the risk of structural damage. Strong sunlight exposure may cause some plastic and fabric materials to age and fade. Frequent mechanical collisions or vibrations can also accelerate the wear and loosening of top decorations. Therefore, when purchasing and installing, environmental factors should be fully considered, suitable materials and structural designs should be selected, and corresponding protective measures should be taken to improve the safety of the top decoration in a specific environment.

Importance of safety testing and quality certification

The safety performance of curtain finials needs to be guaranteed by professional testing and certification. Relevant testing items include material composition analysis, structural strength testing, durability evaluation, and fire performance testing. Obtaining a quality certification mark recognized by the state or industry can provide consumers with certain quality and safety guarantees. Some products on the market have insufficient safety performance. Users should pay attention to the product's test report and certification information when purchasing, avoid using top decorations that do not meet safety standards, and reduce the probability of safety accidents.

Suggestions for safety risk prevention

In order to reduce the risk of curtain finials falling and damage, safety management should be strengthened from multiple links such as design, production, installation and use. The force structure and installation method of the top decoration should be considered in the design stage to ensure reasonable load bearing. Material quality and process specifications should be strictly controlled during the production process. Standard operating procedures should be followed during installation, and suitable fixings should be selected and confirmed to be firmly installed. During use, regularly check the status of the top decoration and deal with any problems found in a timely manner. Through comprehensive preventive measures, the safety of curtain finials can be effectively improved and the user's daily use experience can be guaranteed.

| Safety Factor | Impact Description | Countermeasures |

|---|---|---|

| Installation Firmness | Reduces risk of falling | Use appropriate fasteners and follow standard installation procedures |

| Material Stability | Prevents deformation and cracking | Select durable materials and apply moisture and sun protection |

| Maintenance Frequency | Extends service life and reduces hazards | Perform regular inspections, cleaning, and timely repairs |

| Usage Environment | Lowers risks of material aging and corrosion | Choose materials suitable for the environment and apply protective treatments |

| Quality Certification | Ensures safety performance and reduces risk of substandard products | Select products with relevant testing and certification |