Introduction to Curtain Rods and Environmental Challenges

Curtain rods are essential components in both residential and commercial interior design, supporting curtains while contributing to the aesthetic of a space. The performance of curtain rods can be affected by environmental factors, particularly humidity and sunlight. In humid environments, metal rods are prone to corrosion or rust, while prolonged exposure to sunlight can cause fading or degradation of finishes, especially on painted or coated rods. Understanding the resistance of different curtain rod materials and finishes to these environmental challenges is essential for ensuring durability and long-term performance.

Materials Commonly Used for Curtain Rods

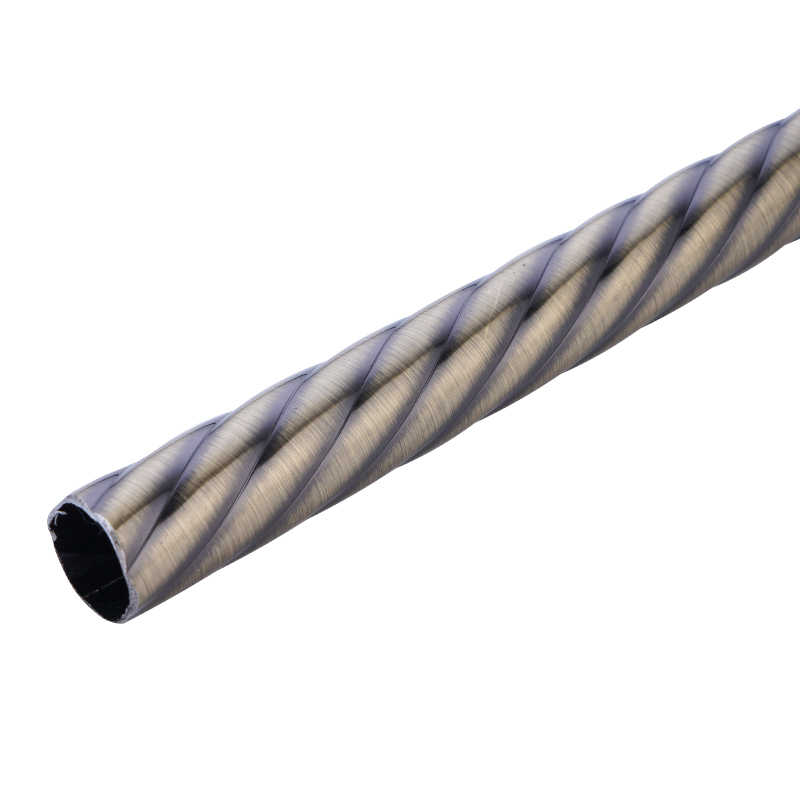

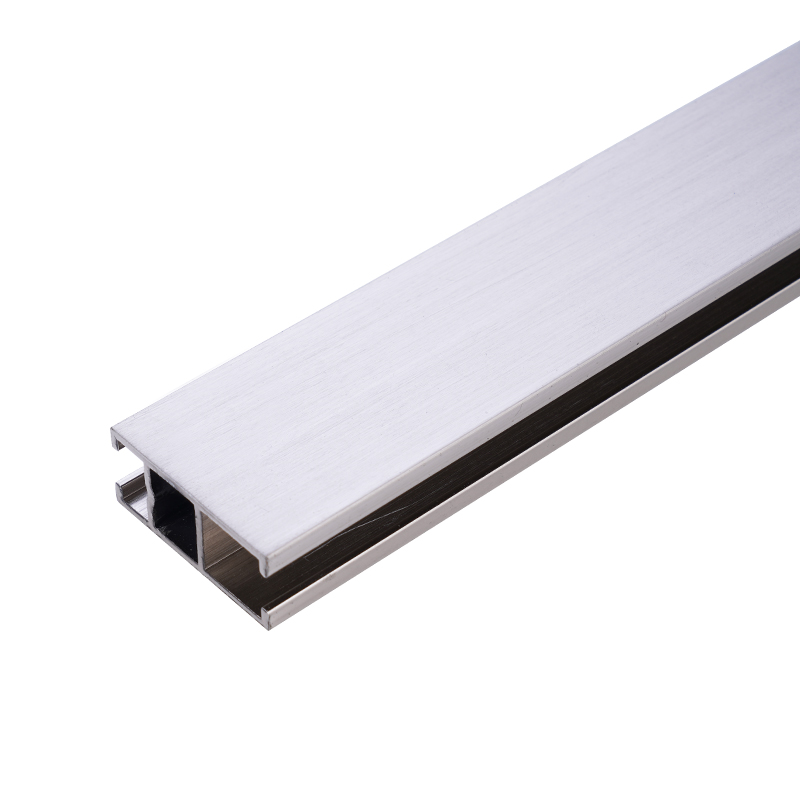

Curtain rods are made from a variety of materials, including metals like stainless steel, aluminum, and iron, as well as non-metals such as wood, plastic, and composite materials. Each material has inherent advantages and limitations regarding corrosion, rust, and fading. Metals generally offer higher mechanical strength but may require protective coatings to resist corrosion. Wood provides natural aesthetics but can warp or discolor under humidity or sunlight. Plastic and composite materials are often lightweight and resistant to moisture but may fade under prolonged sun exposure.

| Material | Corrosion Resistance | Fading Resistance | Typical Use Cases |

|---|---|---|---|

| Stainless Steel | High, naturally resistant | Moderate, depends on finish | Residential, humid areas |

| Aluminum | Moderate, may oxidize | Moderate, may dull over time | Indoor and outdoor applications |

| Iron | Low, prone to rust | High if painted or coated | Traditional decorative rods |

| Wood | Low to moderate, depends on treatment | Low to moderate, may discolor | Indoor aesthetics |

| Plastic | High, not prone to rust | Low to moderate, may fade | Light-duty curtains |

Corrosion and Rust in Humid Environments

Humidity is a significant factor that affects metal curtain rods. Iron and other ferrous metals are particularly susceptible to rust if exposed to moisture over time. Stainless steel and aluminum exhibit better resistance due to natural or treated oxide layers. Protective coatings, such as powder coating or electroplating, further enhance corrosion resistance. In environments like bathrooms, kitchens, or tropical climates, choosing rods with high resistance to moisture or ensuring proper maintenance can prevent degradation and extend lifespan.

Corrosion and Rust Susceptibility

| Metal Type | Natural Resistance | Effect of Protective Coating | Recommended Environment |

|---|---|---|---|

| Stainless Steel | High | Enhances appearance and lifespan | Bathrooms, kitchens, humid regions |

| Aluminum | Moderate | Prevents minor oxidation | Indoor living rooms, moderately humid areas |

| Iron | Low | Essential to prevent rust | Dry indoor spaces or well-coated outdoor use |

Fading and UV Exposure

Curtain rods exposed to direct sunlight may experience fading or discoloration, particularly those with painted or powder-coated finishes. Wooden rods can discolor or warp under prolonged UV exposure, while some plastics may yellow or become brittle over time. To mitigate fading, finishes can include UV-resistant coatings, while placement strategies such as using curtains to shield rods or installing rods in less exposed areas also help maintain appearance.

| Rod Material | UV Susceptibility | Mitigation Measures |

|---|---|---|

| Stainless Steel | Low to moderate, may dull | Polishing, UV-protective coating |

| Aluminum | Moderate, surface oxidation | Powder coating with UV resistance |

| Iron | Low, paint may fade or peel | Repainting, UV-protective coating |

| Wood | High, discoloration and warping | Staining, varnish with UV protection |

| Plastic | Moderate, may yellow | UV stabilizers in material, indoor placement |

Protective Finishes and Treatments

Finishes play a crucial role in improving the resistance of curtain rods to environmental degradation. Powder coating provides a hard, protective layer that resists moisture and UV exposure. Electroplating can enhance both corrosion resistance and aesthetic appeal. Wooden rods can be treated with varnish, lacquer, or oil to improve moisture resistance and prevent fading. Regular maintenance, such as cleaning and reapplying protective finishes, is also essential in high-humidity or high-sunlight environments.

Protective Treatments and Benefits

| Finish/Treatment | Function | Suitable Material |

|---|---|---|

| Powder Coating | Prevents rust, reduces UV fading | Metals (Iron, Aluminum) |

| Electroplating | Corrosion resistance, visual appeal | Metals (Iron, Steel) |

| Varnish/Lacquer | Moisture barrier, reduces fading | Wood |

| UV Stabilizer | Reduces yellowing, prolongs appearance | Plastics |

Installation Considerations for Durability

Proper installation contributes to long-term resistance to corrosion and fading. Rods should be mounted securely to reduce stress and minimize contact with water-prone areas. Avoiding direct exposure to sunlight through careful placement or using curtain linings helps reduce fading. Ensuring that mounting hardware, such as brackets and screws, is made of corrosion-resistant materials also enhances overall performance.

| Installation Factor | Effect on Durability | Recommendation |

|---|---|---|

| Mounting Location | Reduces moisture and UV exposure | Install away from windows exposed to direct sunlight or near water |

| Bracket Material | Prevents rust on critical points | Use stainless steel or coated hardware |

| Clearance | Avoids water contact | Keep rods above potential water splash zones |

Comparison of Resistance Across Environments

When comparing curtain rods across different environments, it is clear that material selection, finish, and installation practices all influence performance. Stainless steel and powder-coated rods are most resilient in humid areas, while UV-resistant finishes on metals and plastics help maintain appearance in sunny spaces. Wooden rods require additional treatments to sustain their aesthetic and structural integrity.

| Environment Type | Recommended Material/Finish | Expected Performance |

|---|---|---|

| High humidity (bathroom/kitchen) | Stainless steel, powder-coated iron | Resists rust, retains shape |

| Direct sunlight (living room, sunroom) | UV-protected aluminum, treated wood | Maintains color, prevents fading |

| Indoor moderate conditions | Plastic, untreated metal, wood | Adequate, minimal maintenance |

Maintenance Practices

To prolong the lifespan of curtain rods, regular maintenance is important. This includes cleaning to remove dust and moisture, checking for signs of corrosion or discoloration, and reapplying protective coatings as needed. In humid or sunny environments, periodic inspections ensure early detection of potential issues, allowing corrective action before structural or aesthetic damage occurs.