Basic composition of curtain rod structural design

The structure of the curtain rod is mainly composed of the rod body, bracket, fixings and connectors. The rod body is usually the main part that bears the weight of the curtain. The bracket is responsible for fixing the curtain rod to the wall or ceiling, and the fixings and connectors ensure the tight connection of each part. The rationality of the structural design is directly related to the stability and durability of the curtain rod. Design defects in any link may lead to a decline in overall performance.

Material selection and structural coordination

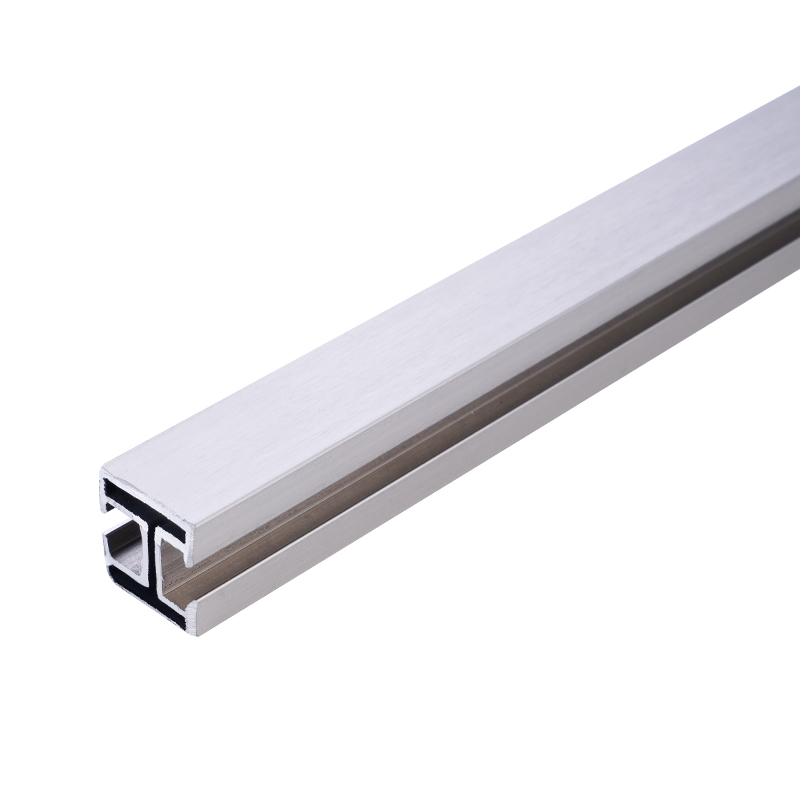

The stability and durability of the curtain rod are first affected by the material. Different materials have different mechanical strength and corrosion resistance. Common materials include aluminum alloy, stainless steel, iron and plastic. The structural design needs to be optimized according to the material properties. For example, the metal rod body often adopts a hollow circular tube design, which can reduce weight and maintain strength. The coordination of materials and structural design can prevent the rod body from deformation or breakage due to long-term load-bearing.

Rod body diameter and wall thickness design

The diameter and wall thickness of the curtain rod are key parameters affecting stability in structural design. A larger diameter and appropriate wall thickness can improve the bending resistance of the rod body and reduce sagging or deformation when bearing the weight of the curtain. Too thin a wall thickness may lead to insufficient strength of the rod, which is prone to bending and breaking; while too thick a wall thickness may increase strength, but it will also increase deadweight, making installation and use inconvenient, and costly. Therefore, reasonable diameter and wall thickness design are important factors to ensure the stability of curtain rods.

Bracket design and distribution

The bracket is an important component for fixing curtain rods, and its structural design directly affects the stability of the entire curtain rod system. The number, shape and fixing method of the bracket need to be designed according to the length and load-bearing requirements of the curtain rod. Generally, the brackets should be evenly distributed to avoid concentrated load-bearing and local deformation of the rod. The bracket itself needs to have sufficient strength and rigidity to prevent loosening or breaking due to shaking or external forces during use.

Design details of connectors

The curtain rod often needs to be adjusted in length according to the width of the window, and the connector design facilitates the splicing and disassembly of the rod. The connector structure should ensure the stability and tightness of the splicing to prevent shaking or separation during use. Reasonable connection design should also facilitate installation and maintenance, and reduce safety hazards caused by structural looseness. Sealing treatment of the joints also helps prevent corrosion and wear and extend service life.

The influence of fixing method on stability

The fixing methods of curtain rods include wall-mounted, ceiling-mounted and hanging types, and the structural design needs to adapt to different installation requirements. Wall-mounted ones are usually fixed to the wall with screws. The load-bearing capacity of the wall and the firmness of the fixings should be considered during the design. The ceiling-mounted type is fixed to the ceiling, and the load-bearing structure of the bracket needs to be designed to ensure safety. Different fixing methods have different effects on the stress state of the curtain rod. Reasonable fixing design helps to improve the overall stability and prevent loosening or falling off during installation.

Anti-bending and anti-torsion design

While the curtain rod bears the weight of the curtain, it will also be affected by external forces such as pulling, pushing and pulling. The structural design needs to focus on the anti-bending and anti-torsion properties of the rod body to avoid deformation of the rod body during use. The use of reinforcing ribs, thickened walls or multi-layer composite structures are common design methods. A curtain rod with a reasonable structure can effectively resist various forces generated during use and maintain the stability of its shape and function.

The auxiliary role of surface treatment on durability

Although surface treatment is not a direct content of structural design, it is closely related to structural design. Reasonable surface treatment such as spraying, rust prevention, anodizing, etc. can improve the corrosion resistance of materials and reduce structural damage caused by environmental factors. The structural design should consider the adaptability of surface treatment to avoid the treatment layer falling off, exposing the internal material and accelerating the damage process.